Technology

HOW MUST MACHINES BE DESIGNED TO TRANSFORM & PRESERVE RESOURCES?

#01 +X01

Y2024+

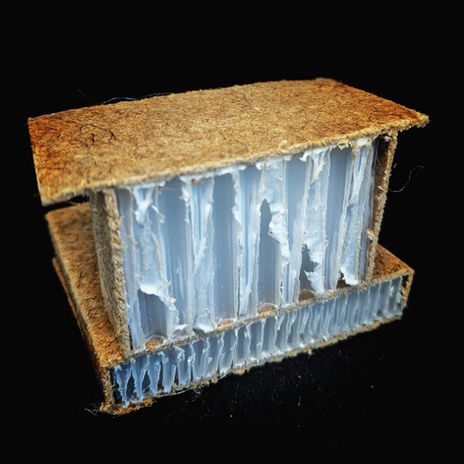

#01 marks the initial step in MeSentia's development series for producing lightweight panels and pallets. This project involves validating fundamental technologies and constructing prototypes crucial for later sales projects and machines. #01 is essential for progressing to #02 as it establishes the foundations for further developments and demonstrates how individual basic processes can later be automated. These processes include integrating long fiber reinforcements to enhance the mechanical properties of the panels, developing half-shells from lightweight, stable material, and applying welding techniques.

The research and development project X01 addresses all necessary measures in handling the waste raw material—yes, there are dangers not only on the processing side but also regarding reproducibility. This is followed by analysis processes to ensure that all MeSentia machines are fed with accurate data and parameters, reducing risks with concrete measures in handling! We aim to create a maximally safe environment, implementing necessary safety measures to protect people, machines, and the environment.

#02

Y2025+

#02 represents the second phase in MeSentia's development series, focusing on the expansion and scaling of the technologies developed in #01+#X01. This phase includes the design and construction of a facility for manufacturing lightweight panels and pallets.

The timeline includes a three-month preparation phase, followed by a six-month development phase. Subsequently, #02, a fully automated European pallet production line, will elevate our technology to TRL 7/8.

The total timeline for this is 15 months.

The facility measures approximately 20m x 30m x 3.8m and has a capacity of 800,000 to 1,300,000 pallets per year (operating three shifts and 240 working days annually).

#03

Y2025+

Building on #02 (or directly following #01), #03 will be developed, a simplified version for producing a single type of panel, operated via a remote-controlled robotic system.

The dimensions are approximately 4.8m x 12m x 3.8m, with a capacity comparable to that of #02.