HOW DOES MACHINERY TECHNOLOGY REVOLUTIONIZE THE PRODUCTION OF SUSTAINABLE LIGHTWEIGHT PANELS?

Technology

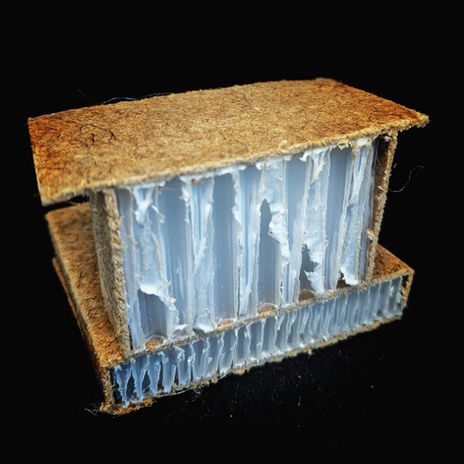

A process and device for manufacturing sustainable lightweight panels (fully edge-sealed honeycomb panels) made from recycled plastics, revolutionized by modular and scalable machinery technology, have been filed for patent.

Solution

MeSentia's innovative solution utilizes a newly developed process technology for producing lightweight panels with a sophisticated honeycomb structure.

This groundbreaking technology uses low-grade plastic combined with reinforcing fibers from agricultural by-products, offering a sustainable alternative to high-quality wood and premium thermoplastics.

With a filed process patent, our solution is distinguished by its environmental friendliness, as it consists of 100% recycled materials and operates within a fully closed-loop system, allowing for seamless recycling into equivalent products.

To enhance performance, fibers from agricultural by-products or recycled materials, such as hemp stalks from oil production, can be incorporated.

The process is technically straightforward and energy-efficient, enabling cost-effective production in rural areas lacking adequate recycling infrastructure, thereby boosting sustainability efforts.

Further product testing has revealed potential applications beyond logistics, including packaging, furniture manufacturing, and aircraft construction.

Technology Readiness Level (TRL)

5

successfully labtested

Y2023

Currently at TRL 5, using a modified machine from Steton, Italy-based leader in wood processing machinery. We validated our technology's functionality under real-world conditions, performance, and reliability.

Our next step is #01/#X01 demonstrator and research project, aiming for TRL 6, focusing on demonstrator construction techniques over a 9-month timeline.

Subsequently, #02, a fully automated pallet (logistic modul) production line, will advance our technology to TRL 7/8 in 15 months, with a capacity of 800,000 to 1,300,000 pallets annually.

Following #02, a simplified version #03 is planned (producing a single type of lightweight panels), which will be operated remotely with robotic systems.

The process patent, titled 'Method and apparatus for the production of plastic building panels,' was filed on 27.07.2023 under European patent registration number 23 188 220.0. It has been confirmed in 11 central points in the preliminary report by the EU examiners. Efforts are underway to secure protection rights globally.